Automation of nickel plating and copper installations by Iwaki Belgium

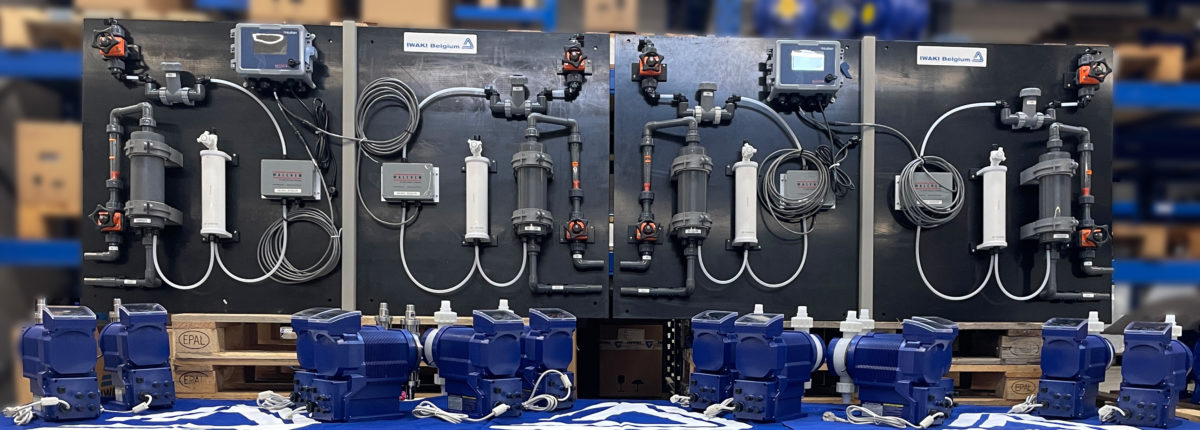

We recently built fully equipped panels with Walchem Intuïtion 6 controllers for a customer who was looking for an automation solution for all his nickel plating baths.

The nickel-plating process is based on 3 parameters: Nickel Sulfate concentration, Hypo concentration and pH.

A cooler is installed on the panel to cool down the sample liquid to an acceptable temperature (35°C), which is necessary for durable and reliable pH control.

The degasser will remove gas bubbles to ensure reliable reading of the nickel sensor.

The nickel concentration is measured by the Walchem nickel sensor. Based on this measurement, Nickel Phosphate and Hypo are added automatically by our Iwaki IX-C dosing pumps to the nickel bath.

As pH is a crucial factor for uniform plating, it’s important to measure the pH so an acid or base can be added to maintain the required pH level.

We supplied complete package together with 6 Iwaki IX-C dosing pumps.

Advantages:

- Increased quality of the end-product

- Continuous quality control

- Automation of the process

- More efficient

- Lower labour cost

- …

Looking for a way to automatize your process?

Get in touch with Iwaki Belgium!